What separates Duro-Last from its competitors

Industry-Leading Warranties

Duro-Last warranties provide unparalleled protection for commercial roofing applications. Duro-Last the first manufacturer to offer a warranty that expressly covers consequential damages.

Code Approvals

Duro-Last roofing membranes meet or exceed major national fire and wind code requirements as well as most required regional approvals throughout the country.

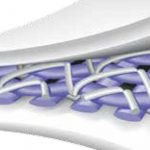

Superior Scrim

Knitted in-house, the anti-wicking polyester weft-insertion scrim has a 14 x 18 or 14 x 9 threads-per-inch density – among the highest in the industry. Duro-Last’s scrim uses a third tie yarn to prevent runs and doesn’t allow tears to spread. The scrim is the backbone of all Duro-Last’s membranes, giving them their strength and puncture resistance.

Performance Layer

Duro-Last’s thickness over scrim – also known as the “performance layer” – is thick, making our membranes extra durable. This means that Duro-Last Roofing Systems provide protection where buildings need it most: the exposed surface of the membrane.

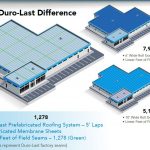

Prefabricated Deck Sheets

Energy & Recycling

By reflecting up to 86% of the sun’s energy, Duro-Last’s white membranes can greatly reduce energy consumption and costs. With a total solar

emittance of up to 95%, the Duro-Last membrane is ENERGY STAR® qualified, meaning our roofing systems release energy and heat efficiently. Due to Duro-Last membrane being prefabricated there is less waste. Duro-Last scientist have developed procedures to turn membrane waste or old material into recycled flooring, walk way pads or concrete expansion joints preventing further landfill waste.